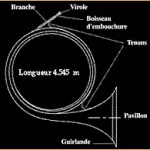

Anatomy of the instrument

The trunk is made up of several assembled tubes, totaling a length of 4.545 meters. This length determines the key which remains fixed: that of D, the fundamental note from which the others are produced. The diameter of the tube, or “pierces”, increases from the mouthpiece branch to the bell (characteristic which contributes in part to the particular timbre of the horn). This progression is regular up to the roof tube where it is accentuated. The best horns have a cobblestone pavilion, that is to say, hammered for a long time. This operation, called “work hardening”, hardens the metal and gives stamp. As for the garland which circles the edge of the pavilion, it does not only have a decorative function. Not welded but simply crimped, it increases rigidity and slows down the tendency of the horn to vibrate at its own frequency which would scramble the tone.

Making a good hunting horn … Not that easy!

Pushing, sheet metal work, bending, welding… the general principles of instrument making are well known. A worthy pupil of Raoux in the 19th century, François Périnet knew how to optimize them in terms of solidity, timbre, ease of emission, sound volume …

To do this, it has notably developed a new roof profile, a model since adopted by all manufacturers and which remains the benchmark. So even today, some ringers happily use instruments dating back over 150 years.

But in two centuries, much has changed. Faced with demand, many manufacturers have contented themselves with reproducing instruments by favoring the exterior appearance to the detriment of acoustic and musical performance. However, the market has evolved over time, technically, economically or otherwise, and these challenges must be constantly addressed. We can mention pell-mell:

- A new approach to the instrument thanks to breathing techniques borrowed from other brass instruments or from singers.

- Stronger demands on ease of issuance and stamp quality.

- The increased technicality of manufacturing equipment and the intervention of IT.

- The ban on certain materials, such as lead formerly used for bending or the black of the flag.

- The increase in the number of bell ringers, requiring adapted production capacities.

- The qualification and cost of labor, which have a significant impact on prices.

- Etc.

History of Maison Périnet

For the amateur of old horns, the table below retraces the successive stages of the mark and makes it possible to date a period instrument according to the address which it carries.

Paris

François Périnet – 1829-1838

42, rue Bourbon Villeneuve - Paris

François Périnet – 1838-1849

23, rue des Bassins - Passy

François Périnet – 1849-1858

23, rue des Bassins - Passy

François Périnet, Pettex-Muffat & Cie – 1859-1862

rue des Bassins, 23 - Passy

François Périnet, Pettex-Muffat & Jolly Pottuz succr. – 1863-1864

23, rue Copernic - Paris

François Périnet, Pettex-Muffat & Jolly Pottuz succr. – 1865-1869

37, rue Copernic - Paris

François Périnet, Pettex-Muffat & Jolly Pottuz succr. – 1870-1871

37, rue Copernic, près de l‘arc de l’étoile - Paris

François Périnet, Pettex-Muffat & Jolly Pottuz succr. – 1871-1874

27, rue Copernic, près de l‘arc de l’étoile - Paris

François Périnet, Pettex-Muffat & Jolly Pottuz succr. – 1874-1882

31, rue Copernic, près de l‘arc de l’étoile - Paris

François Périnet, Pettex-Muffat & Jolly Pottuz succr. – 1883-1895

31 rue Copernic, près l‘arc de l’étoile - Paris

François Périnet, Henri Pettex-Muffat succr. – 1900-1904

40 bis, rue Fabert - Paris

François Périnet, Emile Dhabit succr. – 1905-1923

40 bis, rue Fabert - Paris

François Périnet, Maurice Valéry succr. – 1921-1939

40 bis, rue Fabert - Paris

François Périnet, Tutin & Cheval succr. – 1940-1944

40 ter, rue Fabert - Paris

François Périnet, Cheval succr. – 1945-1967

Périnet - Paris

François Périnet, Michel Bureau succr. – 1967-1994

Viaduc des Arts - Paris

François Périnet, Bureau succr. – 1994-1999

Paris

Périnet, Bureau succr. – 2000

What is a good trunk today?

The one that gives the best sound without requiring exaggerated efforts, of course! But this obvious fact, which might be trivial, actually covers many factors which all have a role to play in a quality objective.

First of all, it is difficult to talk about a trunk without talking about a mouthpiece: both go hand in hand, and one cannot expect good results without a good match between the two. This must be remembered to judge the quality of an instrument.

Often used as a quality criterion, the weight of the horn is simply a result of the thickness of the metal and has little impact, apart from better impact resistance (on horseback, however, the weight is not neutral. ). The Périnet tubes are mainly made in 3 / 10ths, some in 2 / 10ths for women, thicknesses which ensure excellent strength without excess weight.

Le métal utilisé est le laiton, un alliage de cuivre et de zinc : c’est une matière facile à mettre en forme et qui offre aussi l’avantage de favoriser la propagation des fréquences sonores. Son choix est donc primordial. L’alliage que nous utilisons est sélectionné sur trois critères principaux: la qualité acoustique, la résistance et la tenue dans le temps.

The work of metal represents finally an element of first importance. This is where the art of the manufacturer comes in from the model to be produced (today computerized [CAD], the design meets rigorous standards which go beyond the scope of this article).

High precision know-how

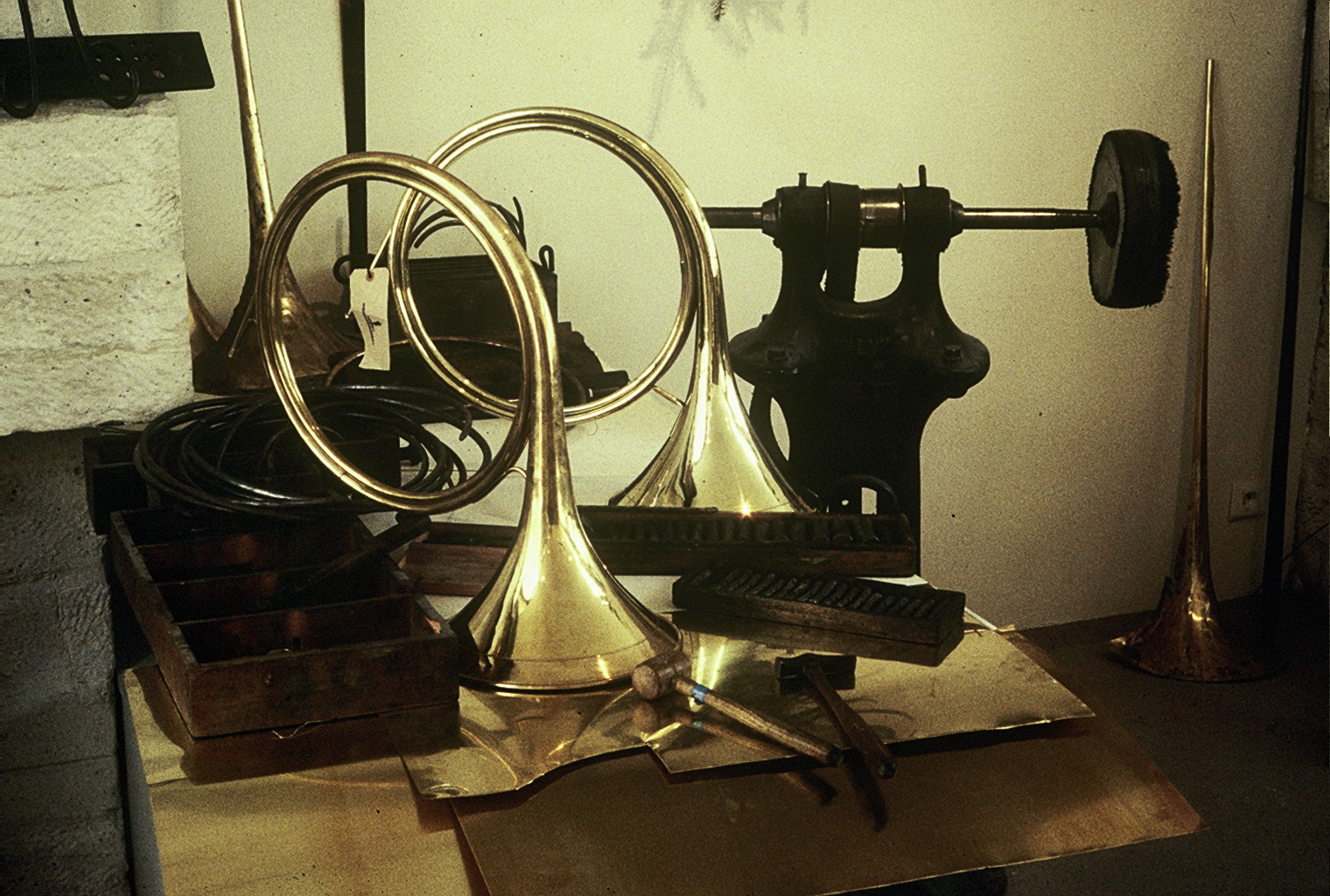

The pavilion can be produced using two methods. In the first, embossing, a rotating mandrel (mounted on a lathe) is used with the profile of the pavilion to be produced; using special tools, the brass sheet is gradually pushed back until it matches the shape of the mandrel.

For top-of-the-range horns, we do not use embossing but boilermaking. Here, the metal sheet is shaped by hand hammering on a fixed steel mandrel. A pavilion thus receives several thousand blows of the mallet. This operation, known as “hardening”, causes molecular restructuring which hardens the metal and makes it more sonorous. The timbre of the instrument gains a lot in finesse of sound and harmonic richness. A leveling completes the operation to make the surface perfectly smooth.

The planking then stiffens the pavilion thanks to a garland turned upside down on its edge, with a brass wire inside.

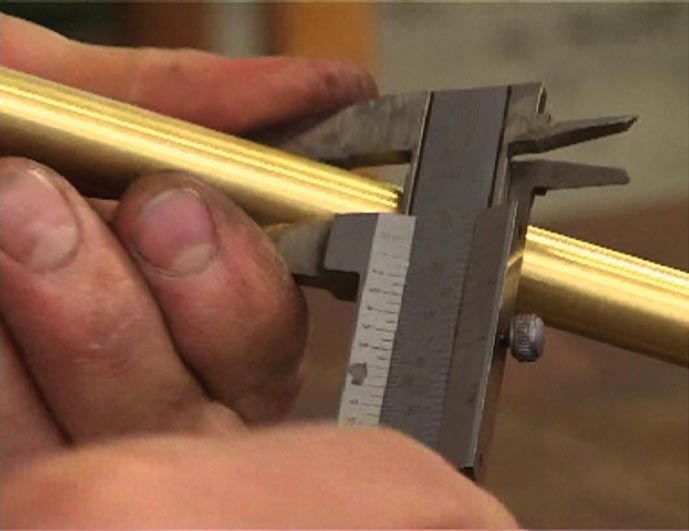

Then the tubes are chosen according to their diameter and worked on a bench to stretch. It is a question of bringing them to the exact dimension, an operation which requires great precision. The mouthpiece branch is the subject of particular care because it plays an essential role: it is this which receives the breath and accelerates it to give birth to the sound, thanks to the inverted cones that it forms with the mouth. The tail of the mouthpiece must be able to fit exactly in the plug provided for this purpose at the inlet of the tube.

This device depends, among other things, on what is called the support. This is the resistance that the instrument opposes to the breath and without which the vibrations of the lips would be difficult to control. This resistance is more or less important according to the bore, that is to say the diameter of the tube. We can thus make instruments with different bores to allow the ringers to choose the support that suits them best.

Once prepared, the tubes are bent on suitable templates. Traditionally, lead was poured inside to be able to bend them without causing crushing or cracks. Once the operation was completed, the lead was melted away, but sometimes leaving unwanted residues. It is now replaced by ice, a solution that keeps the inside of the tube perfectly clean while eliminating the risks associated with the use of this metal.

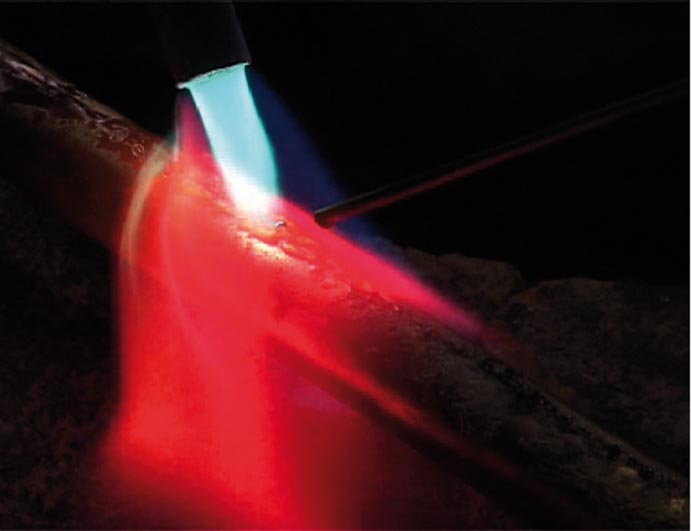

All the elements then undergo pre-polishing before being assembled by tin brazing. This should be thin enough not to weigh down the proboscis, but strong enough to ensure its strength. Tenons complete the cohesion of the whole and a ferrule reinforces the end of the mouthpiece tube. Finally, the mounted instrument is polished with a brush with a polishing paste.

It remains to be tested to ensure the fullness of the sound (in the treble as in the bass), the quality of the timbre, the accuracy in all registers, ease of emission, etc. You should know, however, that a trunk gets better with use, and that the best way to maintain it … is to ring!

The final finishes are provided with the engraving of the brand on the garland and the number of the instrument on the mouthpiece, the black of the bell being applied last with a special paint which guarantees good resistance over time.

Despite its apparent simplicity, the trunk therefore calls for its manufacture on complex know-how which today combines the achievements of modern technology with irreplaceable artisanal experience.

It is also the bell ringer who makes the horn

However thorough the search for quality is, however, it would be worthless without the quality of the ringer himself because the best of instruments will not perform miracles in their place. Today we know how to avoid mistakes that discourage or limit too many beginners.

The sound is produced by the column of air contained in the horn, when it is resonated by the vibrations of the lips in the mouthpiece under the action of the breath. This is why breath control is essential for a good instrument to reveal all its possibilities. Based on abdominal breathing (also used in relaxation methods), this simple technique is available to everyone, women and men, young and old.

With a mastered breath and a good trunk, ringing is no longer a difficult effort but quite simply a pleasure.